Introduction:

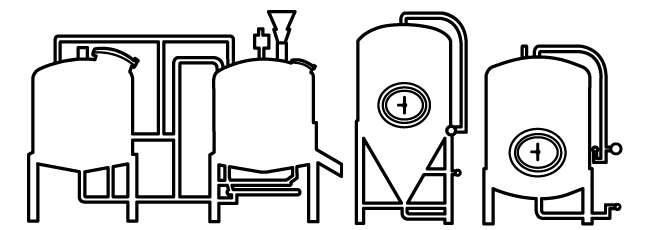

The keg washer is specially designed for washing and sterilizing various beer fresh-keeping containers, such as stainless steel barrels, plastic beer barrels and fresh beer barrels. It can automatically accomplish all of the procedures of washing, sterilizing and CO2 pressure preparing.

Specification:

| DIMENSION OF OPERATING PLATFORM (L*W) | 400×1500 mm |

| HEIGHT OF OPERATING PLATFORM (H) | 800 mm |

| DIMENSION OF MACHINE FIGURE (L*W*H) | 2000x900x1500 mm(Raises Type) |

| NET WEIGHT | 245kg |

| CAPABILITY | 90-120 barrels/hour (10L barrels) |

| AIR CONSUMPTION | 8-22.5 m. cube/h |

| WATER CONSUMPTION | 1-3 m. cube/h |

| POWER | PUMP750W*2 |

| Air Source Pressure | 0.6-0.8Mpa |

| Cylinder Pressure | 0.4-0.5Mpa |

| CO2 Pressure | 0.2-0.3Mpa |

| Steam Pressure | 0.15-0.2Mpa |

| Hot Soda-water Temperature | 60-70℃ |

| Hot water Temperature | 60-70℃ |

| Sosa-water potency | 1%-2% |

| Voltage, Amp. | AC 220V 60Hz 3 phase, 20A |

How to operate keg washer/filler:

Preparation:

Operation:

Your Comments Are Important:

Based upon your feedbacks, the system has changed to

1. Have casters for mobility(Thanks to Janet)

2. Fill keg standing up, on the ground, so you won’t lift a

filled keg, and increase the filling speed(A few contributors).

3. Facilitate cleaning with cleaners besides sanitizers(Thanks

to Cody). Starting from April 2013, the control panel will have a Cycle

switch with value of 1 and 2.

4. Fixed Emergency Stop bug in the two cycle LOGO program. Reported by Justin. Sept. 4, 2013.

With the value of 1(First Program), the system will act like the units shipped before April 2013; with the value of 2(Second Program), the system will use the following sequences:

1.) Air Pressure -> Drain

2.) City Water Rinse (Aseptic) -> Air pressure to Drain

3.) Hot Water w/ Cleaner (From Hot Water Tank) -> recycle with Air pressure return to Hot water tank (since the keg was rinsed with fresh water, its ok to re-use the cleaner)

4.) City Water (Aseptic Rinse) (this step also lowers the keg temperature so that its not too hot for the cold sanitizer -> Air Pressure to Drain

5.) Sanitizer -> recycle with CO2 Pressure (not air) to Sanitizer tank

6.) CO2 purge and pressure

System shipped before April 2013, can update the system and set B074 as ON. See next section.

Parameter list for the First Program and Second Program of washing cycles:

| First Program | Parameter |

| B002 | Enclosing Time |

| B003 | Air Drain |

| B004 | Water rinse |

| B017 | Pump Emptying |

| B005 | Water drain |

| B006 | Hot Water Wash |

| B007 | Hot Water Recycle |

| B008 | Sanitizer rinse |

| B069 | Recycle to Sanitizer |

| B034 | Purified Water |

| B040 | Purified Water Recycle |

| B013 | CO2 Fill |

| Second Program | Parameter |

| B023 | Enclosing Time |

| B035 | Air Drain |

| B039 | Purified Water Wash |

| B070 | Air Drain 2 |

| B071 | Hot Water Wash |

| B073 | Air push to hot tank |

| B075 | Purified Water Wash 2 |

| B077 | Air Push to drain |

| B080 | Sanitizer Wash |

| B082 | CO2 Push to Sanitizer Tank |

| B087 | CO2 Fill |

Useful Resources:

1. Information for updating keg washer to facilitate using cleaner.

2. Switching the filling method to have the keg standing up(for model shipped to you before March 2013).

Connections on the keg washer: